Viral Vector Manufacturing

The Center for Breakthrough Medicines (CBM) operates the world’s largest single-site advanced therapies facility, with over twenty suites focused on scalable production of viral vectors, including Adeno associated virus (AAV), Lentivirus (LVV), HSV, and Adenovirus.

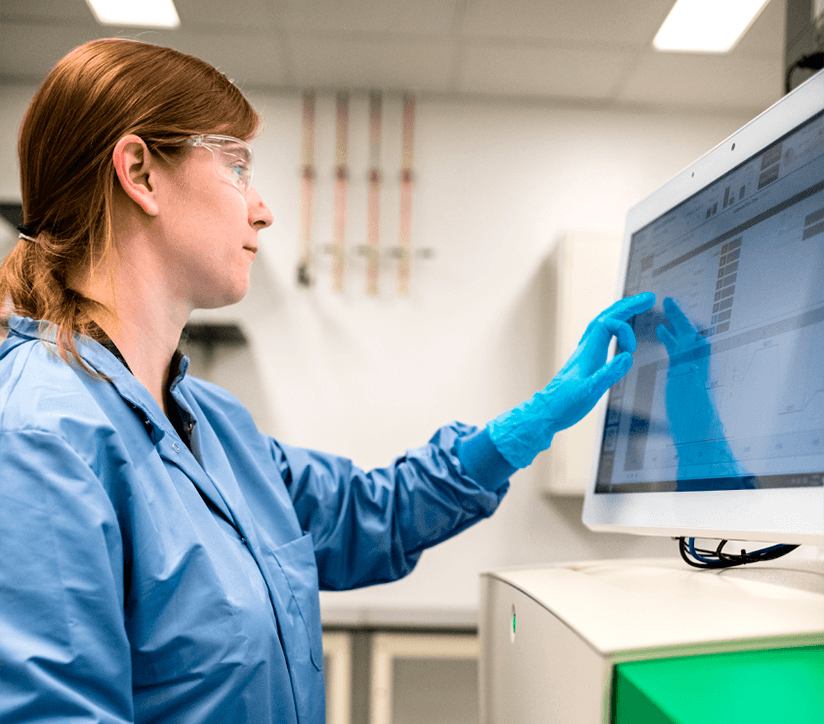

This state-of-the-art site is run by a world-class team, including some of the most experienced people in viral vectors. Our platform solutions efficiently and consistently deliver high yields without compromising quality, accelerating the availability of new therapies to patients who need them.

- Starting material, drug substance, drug product, and custom sterile components and buffers.

- Access to a proven, scalable platform process licensed from Wilson Labs at the University of Pennsylvania.

- Partner in Plant model that offers flexibility for you to work alongside our subject matter experts in our Process Development Labs, to be present during GMP operations in our manufacturing suites, or to remotely monitor your runs via live streaming from the suites.

- Manufacturing and release testing of both raw materials and product destined for clinical trials and commercial supply are performed under cGMP right across the hall from manufacturing.

- Support for client programs throughout the entire product lifecycle from development to commercialization in both adherent and suspension batches up to 2,000 L.

- Allocation of a Scientific Program Leader and a Project Manager to oversee every project, ensuring smooth tech transfers and full transparency throughout your Viral Vector customer journey.

- Process Development drives flawless clinical and commercial GMP manufacturing.

- Option of a dedicated custom cGMP suite under a long-term service agreement.

Facility Design

Starting Materials

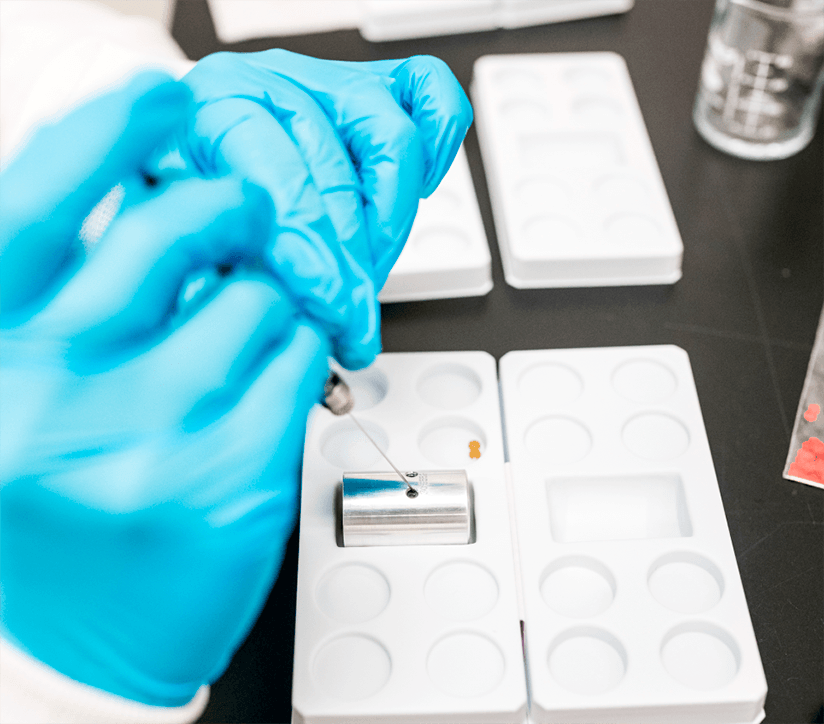

Starting materials are the foundation for long-term quality of your products and therapies, so CBM takes this starting point seriously and provides world-class solutions. As with all our services, everything is integrated on a single site, promoting efficiency and risk mitigation.

- Cell banks

- Viral stocks and viral banks

- Reference standards

Explore Our Assay Tables

Upstream Capabilities

Adherent process for all viral vectors

- Flatware such as HYPERstacks™ and CellSTACKS™ up to 50 x HS batches

- iCellis 500 fixed-bed bioreactors

- Large Grade B and C suites

Suspension process for all viral vectors

- 50 L – 2,000 L capabilities

- Diverse technology vendors to de-risk consumable supply chain

Downstream Capabilities

Harvest and concentration/diafiltration

- Depth filtration

- Tangential Flow Filtration

- UF/DF

Chromatography

- Affinity

- Ion exchange

- Size exclusion

- Hydrophobic interaction

Large-volume ultracentrifugation

Sterile filtration

Drug Product Capabilities

Bausch & Strobel Semi-Automated Filling

- Semi-automated filler, aseptic in design

- Flexible single needle with integrated IPC and closure

- Targeting product hold up <5mL, approximately 3,000 units (2R) per batch

- Range of 0.1-50mL in glass or Crystal Zenith vials

Automated Isolators

- (Vanrx Microcell) supporting 2,400 vials

- (Optima 7000) supporting up to 24,0000 vials

- Same aseptic and single-use philosophy as a higher throughput aseptic Isolator

- Glass and CZ/Polymer capabilities

- 100% IPC and inline CCIT

- 0.1-50ml

- Limited product loss

Visual Inspection and Packaging

- Filled vials go through 100% inspection by qualified operators

- GMP labeling and packaging

Reduced Time out of Refrigeration

Other Capabilities

Plasmid DNA

- Manufacture of plasmid DNA as a critical starting material for the transfection process required for viral vectors

Fill-Finish

- cGMP drug product formulation and fill/finish services

Viral Vectors

CBM’s viral vector platform efficiently and consistently delivers high yields in AAV, Lentivirus, HSV and Adenovirus vectors, accelerating the development of new therapies.

Cell Therapy Manufacturing

CBM has one of the cell therapy’s most experienced teams and the largest single site facility in the industry. There is no greater centralization of expertise.

Our Experienced Team

Our team brings a wealth of experience from biopharma and advanced therapy CDMOs, ensuring that there is no safer place for your product.